Falcon

Production and Launch Operations

Production

The Falcon vehicle stages are produced at SpaceX facilities in El Segundo, California. Unlike most launch vehicle manufacturers, SpaceX is designing and producing its own engines. The vehicle is integrated as four primary assemblies: the first-stage assembly, the interstage, the second-stage assembly, and the payload accommodations. The first- and second-stage assemblies are processed horizontally at the SpaceX facility.

SpaceX headquarters are conveniently located in Hawthorne, CA at 1 Rocket Road, CA 90250, a few miles inland from Los Angeles International Airport. The design and manufacturing facility spans more than 1.5 million square feet and ranks among the largest manufacturing facilities in California; two complete Falcon 9s can fit end-to-end along the short length of the building. Facilities include multiple Falcon 9 and Falcon Heavy manufacturing stations, fairing production and integration stations, nine stations for final assembly of the Merlin engine, and Dragon spacecraft production areas.

Figure 6-9: SpaceX’s headquarters in Hawthorne, California

ROCKET DEVELOPMENT FACILITY — MCGREGOR, TEXAS

Structural and propulsion testing are performed at the SpaceX Rocket Development Facility in McGregor, Texas (Figure 6-10). Conveniently located two hours from both Austin and Dallas, the site is staffed with test engineers, technicians and management personnel.

Figure 6-10: SpaceX Texas test facility and test operations

GOVERNMENT OUTREACH AND LEGAL AFFAIRS—WASHINGTON, DC

SpaceX’s government outreach and licensing team is located in Washington, DC., at 1155 F St. NW, Washington DC 20004.

Launch Operations

Falcon 9 and Falcon Heavy launch operations are designed to be simple—achieving operations as close to “ship and shoot” as possible. SpaceX is able to launch within one week of payload arrival at the launch site—with an ultimate goal of launching within a few hours. This requires limiting payload processing time and efficient on-pad operations. Falcon launch vehicle operations are described in this section for launches from CCAFS and KSC and VAFB. SpaceX launch operations are designed for rapid response (targeting less than one hour from vehicle rollout from the hangar to launch). Customers are strongly encouraged to develop launch readiness capabilities and timelines consistent with a rapid prelaunch concept of operations.

Falcon 9

The Falcon 9 launch vehicle can launch from three launch sites. It is capable of launching from multiple launch sites because of the low level of infrastructure required for launch.

At Vandenberg AFB, SpaceX is using SLC-4E. Both pads were built for use by Atlas-Agena rockets, but were later rebuilt to handle Titan rockets. The designation SLC-4 was applied at the time of the conversion to launch Titans. SpaceX refurbished SLC–4E for Falcon 9 launches in a 24-month process that began in early 2011.

Launches at Cape Canaveral AFS are conducted from SLC-40, which SpaceX has leased from the Air Force since April 2007. At the Kennedy Space Center SpaceX leases Launch Complex 39A from NASA and has modified the pad to support Falcon 9 and Falcon Heavy launches.

Falcon Heavy

The Falcon Heavy can launch from two launch sites: Vandenberg AFB SLC 4E and KSC LC-39A.

The stage assemblies and interstage are shipped separately to the launch site. Once at the site, the stage assemblies are processed horizontally. Flight termination system connections are made and system tests performed. The first stage is stacked onto the launch frame. A dress rehearsal verifies all major first stage functions. The second stage is then be stacked, and mechanical and electrical connections are made, including final FTS integration. Post inspection, a second rehearsal verifies first and second stage functionality.

In parallel with these operations, the payload is integrated to the payload adapter and encapsulated in the fairing in a vertical operation. This assembly is moved to the launch stack and lifted onto the integrated first and second stage. Mechanical and electrical connections are made and interface testing performed. After fueling the vehicle, a final systems check is made to verify full vehicle functionality.

SpaceX generally recovers the first stage of Falcon 9 and Falcon Heavy after launch. This is accomplished with the deployment of a hypersonic drogue with subsequent parachute deployment at 3 km (10,000 ft). Stage 1 is expected to land within 800 km (430 nmi) downrange. A salvage ship is deployed and waiting near the intended impact zone. The stage is expected to float for less than 24 hours while the ship locates it using a beacon mounted on the stage. The recovery ship then tows it to a harbor for pick up and ultimate inspection and refurbishment.

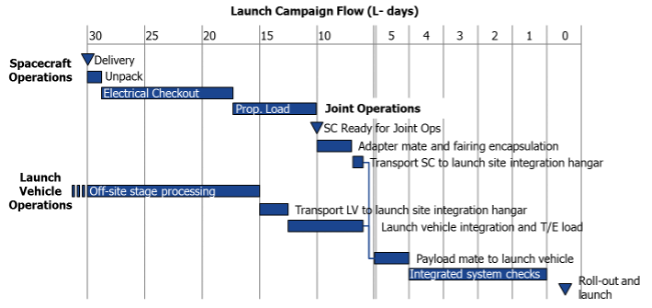

8.1 OVERVIEW AND SCHEDULE

The Falcon launch vehicle system and associated operations have been designed for minimal complexity and minimal time at the pad (Figure 8-1). Customer payload processing is performed in a payload processing facility (PPF). After completion of standalone spacecraft operations (typically over a 20-day period) by L-10 days, SpaceX performs the adapter mate and fairing encapsulation at the PPF. The spacecraft is then transported to the integration hangar. The launch vehicle is processed in the integration hangar at the launch complex and then loaded on the transporter-erector. The encapsulated assembly is mated to the launch vehicle at approximately L-5 days, followed by end-to-end system checkouts. Falcon 9 and Falcon Heavy systems are designed for rollout and launch on the same day, but SpaceX can perform an earlier rollout and conduct a longer countdown if required.

Figure 8-1: Illustrative Falcon launch vehicle processing, integration and launch operations schedule

8.2 SPACECRAFT DELIVERY AND TRANSPORTATION

For standard service processing and integration, payloads should be delivered to the launch site four weeks prior to launch. Alternative delivery schedules can be arranged as a nonstandard service.

Customers typically deliver their payloads via air or ground transport. Cape Canaveral offers two convenient landing locations for customers delivering their payloads and associated equipment via air transport: the Shuttle Landing Facility and the CCAFS Skid Strip. Vandenberg provides one landing location at the VAFB airfield, approximately 14 miles north of the launch complex. Non-US payloads coming to VAFB via the airfield must clear customs at LAX or another port of entry prior to arrival at VAFB.

As a standard service, SpaceX will arrange for the customer’s spacecraft container and all associated test and support equipment to be offloaded from the plane and transported to the payload processing facility. Ground transport services can also be provided by AstroTech Space Operations or Spaceport Systems International; SpaceX can facilitate these as a nonstandard service.

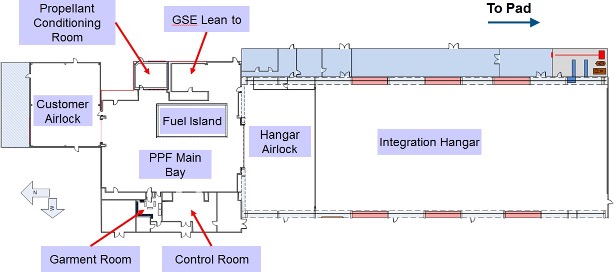

8.3 SPACECRAFT PROCESSING

SpaceX provides an ISO Class 8 (Class 100,000) PPF for processing customer spacecraft, including equipment unloading, unpacking/packing, final assembly, nonhazardous flight preparations, and payload checkout. The payload processing facility is available to customers from four weeks prior to launch, with 16 hours per day standard availability and access during that period. Additional time in the payload processing facility may be available as a nonstandard service. The PPF layouts for VAFB and CCAFS are shown in Figure 8-2, Figure 8-3, and Figure 8-4 respectively.

Figure 8-2: VAFB payload processing facility and integration hangar layout

Figure 8-3: CCAFS PPF East Bay floor plan

Figure 8-4: CCAFS PPF West Bay floor plan

Services and equipment provided for satellite processing within the PPF are outlined in Table 8-1. Additional space is provided for customer ground support equipment and operations personnel. A facility HVAC system maintains payload processing facility environments. SpaceX will continuously monitor relative humidity, temperature and cleanliness in the payload processing facility using particle counters. Cleanliness monitoring using witness plates is available as a nonstandard service. After encapsulation and prior to launch vehicle mate, SpaceX will verify purge media source and ducting cleanliness. The customer must supply any necessary cables and converters for its ground support equipment to interface with payload processing facility power. SpaceX can supply alternative power sources as a nonstandard service.

The PPF is also designed to accommodate hazardous operations such as hypergolic propellant loading and ordnance installation. Any required fueling operations will be performed by customer personnel with assistance from SpaceX personnel. All personnel must use certified SCAPE suits, pass a physical and attend SCAPE training classes.

All spacecraft processing operations within the PPF must be completed by L-10 days to allow for mating to the payload adapter, fairing encapsulation and transportation to the launch vehicle integration hangar in preparation for launch.

Table 8-1: Services and equipment for payload processing

CCAFS | VAFB | ||

Clean room | |||

Dimensions | No less than 29 m x 16.5 m floor size (95 ft x 54 ft) | No less than 29.2 m x 20.7 m floor size (95.8 ft x 67.9 ft) | |

Exterior door | No less than 7.62 m high x 15.24 m wide (25 ft x 50 ft) | No less than 6.01 m high x 6.01 m wide (20 ft x 20 ft) | |

Temp/Clean | See Table 4-2 (PPF facility HVAC) | See Table 4-2 (PPF facility HVAC) | |

Overhead crane | |||

Quantity | 2 | 2 | |

Hook height | 18 m (59 ft) | 18.3 m (60 ft) | |

Capacity | Crane 1: 27,215 kg (30 ton) | North Crane: 27,215 kg (30 T) | |

Hoist Speed (min/max) | 6.1 cm/609 min | 6.1 cm/609 min | |

Operation modes | Independent | Independent or synchronized | |

CCAFS | VAFB | |||

Access equipment | ||||

45-ft boom lifts, pallet jack, lifting | Pallet jack, lifting hardware, ladders, | |||

Electrical | ||||

60 Hz AC | 120 V 1-phase, 120/208 V 3-phase, and | 120 V 1-phase and 120/208 V 3-phase | ||

50 Hz AC | 220/380V – WYE, 3-Phase, 5-Wire with | 220/380V- WYE, 3-Phase, 4-Wire with | ||

Grounding | Per MIL-STD-1542 | Per MIL-STD-1542 | ||

GN2 supply | ||||

Quality | MIL-PRF-27401, Grade B | MIL-PRF-27401, Grade B | ||

Pressure | 34,473 kPa (5,000 psi) | 34,473 kPa (5,000 psi) | ||

Flow rate | 1699.2 Nm3/hr (1,000 scfm) | 1699.2 Nm3/hr (1,000 scfm) | ||

Helium supply | ||||

Quality | MIL-PRF-27407, Grade A | MIL-PRF-27407B, Type 1, Grade B | ||

Pressure | 39,300 kPa (5,700 psi) | 41,368 kPa (6,000 psi) | ||

Flow rate | 1699.2 Nm3/hr (1,000 scfm) | 1699.2 Nm3/hr(1,000 scfm) | ||

Compressed air supply | ||||

Pressure | 758 kPa (110 psi) | 862 kPa (125 psi) | ||

Communications | ||||

Administrative phone | VOIP phones | VOIP phones | ||

Paging system | Yes | Yes | ||

Area warning system | Yes | Yes | ||

Security | ||||

Locking facility | Yes | Yes | ||

Launch site badges | Yes | Yes | ||

Video monitoring | Yes | Yes | ||

As an alternative nonstandard service, SpaceX can arrange the use of commercial processing facilities near CCAFS or VAFB for payload processing. If a payload is processed at a facility other than the SpaceX-provided payload processing facility, SpaceX can provide environmentally controlled transportation from that facility to the launch vehicle integration hangar.

8.4 JOINT OPERATIONS AND INTEGRATION

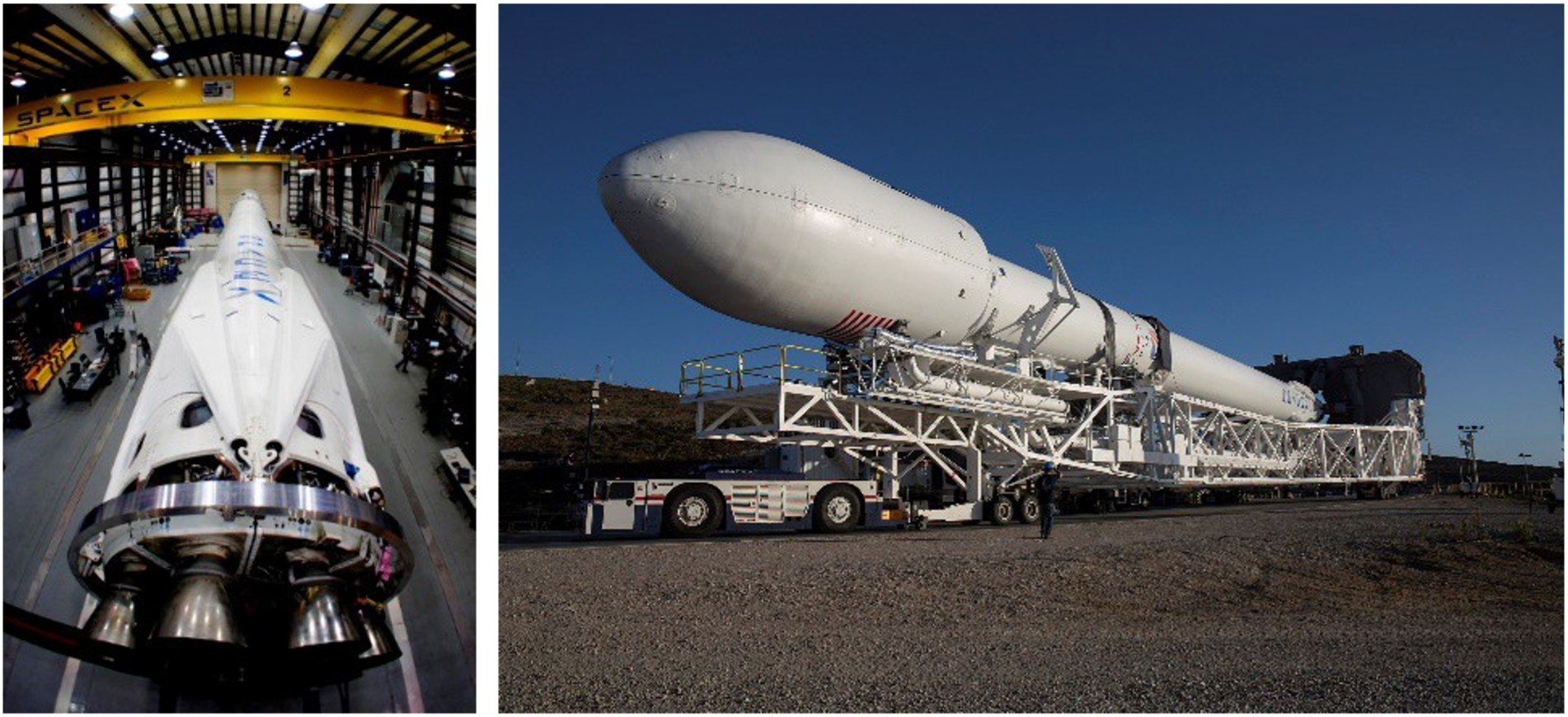

Joint operations begin ten days before launch. Payload attachment to the payload attach fitting and fairing encapsulation are performed by SpaceX within the payload processing facility (Figure 8-5). Fairing encapsulation is performed in the vertical orientation. Transportation is performed in the vertical orientation, and environmental control is provided throughout the transportation activity. Once at the launch vehicle integration hangar, the encapsulated assembly is rotated to horizontal and mated with the launch vehicle already positioned on its transporter-erector.

Figure 8-5: Payload encapsulation and integration sequence

Once the encapsulated assembly is mated to the launch vehicle, the hangar facility HVAC system is connected via a fairing air conditioning duct to maintain environmental control inside the fairing. The payload is then reconnected to electrical ground support equipment (if required) and electrical interfaces are verified. At this point, the integrated launch vehicle is ready for rollout and launch (Figure 8-6).

Figure 8-6: Integrated Falcon 9 on the transporter-erector within the integration hangar and rolling out

8.5 LAUNCH OPERATIONS

8.5.1 ORGANIZATION

The main decision-making roles and responsibilities for launch operations are shown in Table 8-2. Note that this list is not inclusive of all stations participating in the launch, but, rather, is limited to those that have direct input in the decision- making process.

Position | Abbrev. | Organization |

Chief Engineer | CE | SpaceX |

Mission manager | MM | SpaceX |

Launch director | LD | SpaceX |

Missile flight control officer, or | MFCO, or | Launch Range |

Operations safety manager, or ground safety officer | OSM, or GSO | Launch Range |

The launch control organization and its lines of decision-making are shown in Figure 8-7. The details of the launch control organization are somewhat dependent on the mission and customer. The payload manager, or a payload manager representative, will sit at the payload station in the SpaceX launch control center alongside the SpaceX mission manager.

Figure 8-7: Launch control organization

8.5.2 SPACECRAFT CONTROL CENTER

SpaceX provides a spacecraft control center for remote payload command and control operations during the launch countdown. Customer EGSE and spacecraft personnel will be located within the spacecraft control center during launch. The spacecraft control center includes full fiber-optic voice, video and Internet connectivity to the launch site, SpaceX Launch Control (Section 8.5.3), and other range facilities.

8.5.3 LAUNCH CONTROL

The SpaceX console design is modular, expandable and completely modern (Figure 8-8). SpaceX uses standard computer and display systems with software designed for industrial system control. Consoles also include voice communications capabilities, including voice nets, voice-over Internet protocol (IP) integration with remote sites, and IP phones. Video viewing and control are provided using the video-over-IP systems.

Figure 8-8: SpaceX launch control at CCAFS (left) and VAFB (right)

8.5.4 ROLLOUT, ERECTION AND PAD OPERATIONS

After readiness is verified, the integrated Falcon vehicle may be rolled out from the hangar to the pad on its transporter- erector (Figure 8-9). Once the vehicle is at the pad, the payload air conditioning system is reconnected, which helps maintain environmental control through liftoff. Electrical connectivity is provided via ground cables. The vehicle will typically be erected only once, although the capability exists to easily return it to a horizontal orientation if necessary.

Figure 8-9: Launch vehicle rollout and erection

Customer access to the payload while the vehicle is outside of the hangar requires special accommodations and is a nonstandard service. Payload access is not available while the launch vehicle is vertical.

8.5.5 COUNTDOWN

Falcon launch vehicles are designed to support a countdown duration as short as one hour. Early in the countdown, the vehicle performs LOX, RP-1 and pressurant loading, and it executes a series of vehicle and range checkouts. The transporter-erector strongback is retracted just prior to launch. Automated software sequencers control all critical Falcon vehicle functions during terminal countdown. Final launch activities include verifying flight termination system status, transferring to internal power, and activating the transmitters. Engine ignition occurs shortly before liftoff, while the vehicle is held down at the base via hydraulic clamps. The flight computer evaluates engine ignition and full-power performance during the prelaunch hold-down, and if nominal criteria are satisfied, the hydraulic release system is activated at T-0. A safe shutdown is executed should any off-nominal condition be detected.

8.5.6 RECYCLE AND SCRUB

Falcon launch vehicle systems and operations have been designed to enable recycle operations when appropriate. Although every recycle event and launch window requirement is unique, Falcon vehicles offer the general capability to perform multiple recycles within a given launch window, eliminating unnecessary launch delays.

In the event of a launch scrub, the transporter-erector and launch vehicle will stay vertical. Remaining on the pad provides uninterrupted payload-to-EGSE connectivity through the T-0 umbilical, eliminating the need to relocate EGSE from the instrumentation bay to the hangar after a scrub. However, for any long-duration launch postponements, SpaceX will return the vehicle on the transporter-erector to the hangar.

8.6 FLIGHT OPERATIONS

8.6.1 LIFTOFF AND ASCENT

First-stage powered flight lasts approximately three minutes, with commanded shutdown of the nine first-stage engines based on remaining propellant levels. The second stage burns an additional five to six minutes to reach initial orbit, with deployment of the fairing typically taking place early in second-stage powered flight. Subsequent operations are unique to each mission but may include multiple coast-and-restart phases as well as multiple spacecraft separation events.

8.6.2 SPACECRAFT SEPARATION

After reaching the spacecraft injection orbit and attitude, the Falcon vehicle issues a spacecraft separation command, providing the electrical impulses necessary to initiate spacecraft separation. Indication of separation is available in second-stage telemetry.

8.6.3 CONTAMINATION AND COLLISION AVOIDANCE

If a contamination and collision avoidance maneuver is necessary, the second stage performs the maneuver shortly after separation. A contamination and collision avoidance maneuver is provided as a standard service for individual primary payloads. For multi-manifested and secondary payloads, please contact SpaceX regarding collision avoidance requirements.

8.6.4 POST LAUNCH REPORTS

SpaceX will provide a quick-look orbit injection report to the customer shortly after spacecraft separation, including a best-estimate spacecraft separation state vector. A final, detailed post-flight report is provided within eight weeks of launch.

8.6.5 DISPOSAL

SpaceX makes every effort to mitigate space debris by responsibly passivating and disposing of hardware on orbit. Customer-specific requirements on disposal may impose modest reductions to the performance specifications indicated above.

8.7 SAMPLE MISSION PROFILE

Sample mission profiles for Falcon 9 and Falcon Heavy are shown in Figure 8-10 and Figure 8-11, and sample Falcon 9 timelines for a GTO mission and LEO mission are shown in Table 8-3 and Table 8-4. Note: each flight profile is unique and will differ from these examples.

Figure 8-10: Falcon 9 sample mission profile

Figure 8-11: Falcon Heavy sample mission profile

Table 8-3: Falcon 9 sample flight timeline—GTO mission

Mission Elapsed Time | Event |

T - 3 s | Engine start sequence |

T + 0 | Liftoff |

T + 74 s | Maximum dynamic pressure (max Q) |

T + 147 s | Main engine cutoff (MECO) |

T + 151 s | Stage separation |

T + 158 s | Second engine start-1 (SES-1) |

T + 222 s | Fairing deploy |

T + 484 s | Second engine cutoff 1 (SECO-1) |

T + 1636 s | Second engine start-2 (SES-2) |

T + 1696 s | Second engine cutoff-2 (SECO-2) |

T + 1996 s | Spacecraft separation |

Table 8-4: Falcon 9 sample flight timeline —LEO mission

Mission Elapsed Time | Event |

T – 3 s | Engine start sequence |

T + 0 | Liftoff |

T + 67 s | Maximum dynamic pressure (max Q) |

T + 145 s | Main engine cutoff (MECO) |

T + 148 s | Stage separation |

T + 156 s | Second-engine start-1 (SES-1) |

T + 195 s | Fairing deploy |

T + 514 s | Second-engine cutoff-1 (SECO-1) |

T + 3086 s | Second engine start-2 (SES-2) |

T + 3090 s | Second engine cutoff-2 (SECO-2) |

T + 3390 s | Spacecraft separation |

9. SAFETY

9.1 SAFETY REQUIREMENTS

Falcon customers are required to meet AFSPCMAN 91-710 Range User's Manual and FAA 14 CFR Part 400 requirements in the design and operation of their flight and ground systems. These requirements encompass mechanical design, electrical design, fluid and pressurant systems, lifting and handling systems, ordnance and RF systems, ground support equipment, and other design and operational features. SpaceX will serve as the safety liaison between the customer and the range.

9.2 HAZARDOUS SYSTEMS AND OPERATIONS

Most ranges consider hazardous systems and operations to include ordnance operations, pressurized systems that operate below a 4-to-1 safety factor, lifting operations, operations or systems that include toxic or hazardous materials, high-power RF systems and laser systems, and a variety of other systems and operations. The details of the system design and its operation will determine whether the system or related operations are considered hazardous. Typically, additional precautions are required for operating systems that are considered hazardous, such as redundant valving between pressurant and propellant. Additional precautions will be determined during the safety approval process with SpaceX and the launch range. All hazardous operations require procedures that are approved by both SpaceX and the launch range prior to execution. Ordnance operations, in particular, require coordination to provide reduced RF environments, cleared areas, safety support and other requirements.

9.3 WAIVERS

For systems or operations that do not meet safety requirements but are believed to be acceptable for ground operations and launch, a waiver is typically produced for approval by the launch range safety authority. Waivers require considerable coordination and are considered a last resort; they should not be considered a standard practice.

VEHICLE UPGRADE PLANS

SpaceX plans develop the Starship, which will replace the Falcon series of rockets because it will be fully reusable.

SpaceX South Texas launch site, located at Boca Chica, 32 km (20 mi) east of Brownsville on the U.S. Gulf Coast

VEHICLE HISTORY

SpaceX was founded by Elon Musk, who became wealthy as an Internet entrepreneur. A native of South Africa, Musk dropped out of Stanford in 1995 to found Zip2, which was sold in 1999 for $300 million. His second company, PayPal, was sold to eBay for $1.5 billion in 2002. Early in 2002, Musk assembled a team of people experienced with the space launch industry to study whether it was possible to build a low-cost launch vehicle in a developed country with high labor costs. The results of the study were positive, and so Musk founded Space Exploration Technologies (SpaceX) in June 2002. He hired a few dozen managers and engineers from established aerospace companies to build the first Falcon launch vehicle. Development progressed rapidly. In June 2010 SpaceX launched a boilerplate Dragon Spacecraft Qualification Unit into LEO, and in December 2010 SpaceX launched its first Dragon capsule to LEO (ISS) orbit under a NASA Commercial Orbital Transportation Services (COTS) Space Act Agreement with NASA. In October 2012 SpaceX began launches under a Commercial Resupply Services (CRS) contract with NASA.

SpaceX developed the Falcon 9 medium-lift launch vehicle, the Falcon Heavy heavy-lift launch vehicle, the most powerful operational rocket in the world by a factor of two, and Dragon, which is the first commercially produced spacecraft to visit the International Space Station.

SpaceX has built a launch manifest that includes a broad array of commercial, government and international customers. In 2008, NASA selected the SpaceX Falcon 9 launch vehicle and Dragon spacecraft for the International Space Station Cargo Resupply Services contract. NASA has also awarded SpaceX contracts to develop the capability to transport astronauts to space as well as to launch scientific satellites. In addition, SpaceX services the National Security community and is on contract with the Air Force for multiple missions on the Falcon family of launch vehicles.

SpaceX has state-of-the-art production, testing, launch and operations facilities. SpaceX design and manufacturing facilities are conveniently located near the Los Angeles International Airport. This location allows the company to leverage Southern California’s rich aerospace talent pool. The company also operates cutting-edge propulsion and structural test facilities in Central Texas, along with launch sites in Florida and California, and the world’s first commercial orbital launch site in development in South Texas.