Falcon

Vehicle Design

Falcon 9

Falcon 9

Height: 70 m / 230

ft (including both stages, interstage, and fairing)

Diameter: 3.66 m / 12 ft

Gross Liftoff Mass: 549,054 kg / 1,210,455 lb)

Thrust at Liftoff: 981 kN / 220,500 lbf

Thrust in Vacuum:dd

Second Stage Thrust:

Stages Falcon 9

Many of the design features of the Falcon 9 launch vehicle are driven by the desire for reliability and ease of operations. The vehicle is a two-stage design to minimize complexity and the number of staging events. LOX and RP-1 (kerosene) propellants were selected for their ease of handling and safety. Both stages are made of aluminum to eliminate the manufacturing and testing issues associated with composite materials. The empty vehicle is relatively lightweight and can be moved easily. The tanks are structurally stable and can be moved without pressurizing the tanks although pressurization is required to withstand loads in flight.

First Stage

Falcon 9’s first stage incorporates nine Merlin engines and aluminum-lithium alloy tanks containing liquid oxygen and rocket-grade kerosene (RP-1) propellant. After ignition, a hold-before-release system ensures

that all engines are verified for full-thrust performance before the rocket is released for flight. The first stage engines are gradually throttled near the end of first-stage flight to limit launch vehicle acceleration as the rocket’s mass

decreases with the burning of fuel.

Interstage

The Falcon vehicles’ interstage, which connects the first and second stages, is a composite structure consisting of an aluminum honeycomb core surrounded by carbon fiber face sheet plies. The interstage is fixed

to the forward end of the first-stage tank. The stage separation system is located at the forward end of the interstage and interfaces to the second stage.

Second Stage

The second stage, powered by a single Merlin vacuum engine, delivers Falcon 9’s and Falcon Heavy's payload to the desired orbit. The second stage engine ignites a few seconds after stage separation, and can be

restarted multiple times to place multiple payloads into different orbits. For maximum reliability, the second stage has redundant igniter systems. Like the first stage, the second stage is made from a high-strength aluminum-lithium alloy.

Falcon Heavy

Falcon Heavy

Height: 70 m / 230 ft (including both stages, interstage, and fairing)

Diameter: 12.2 m / 40 ft

Gross Liftoff Mass: 1,420,788 kg / 3,132,298 lb

Thrust at Liftoff: 22.819 kN / 5,130,000 lbf

Thrust in Vacuum: 24,681 kN / 5,548,500 lbf

Second Stage Thrust: 845 kN / 190,000 lbf

Stages Falcon Heavy

The vehicle is a two-stage design to minimize complexity and the number of staging events. LOX and RP-1 (kerosene) propellants were selected for their ease of handling and safety. Both stages are made of aluminum to eliminate the manufacturing and testing issues associated with composite materials. The empty vehicle is relatively lightweight and can be moved easily. The tanks are structurally stable and can be moved without pressurizing the tanks although pressurization is required to withstand loads in flight.

First Stage

Three cores make up the first stage of Falcon Heavy. The side cores, or boosters, are connected at the base and at the top of the center core’s liquid oxygen tank. The three cores, with a total of 27 Merlin engines, generate 22,819 kilonewtons (5.13 million pounds) of thrust at liftoff. Shortly after liftoff the center core engines are throttled down. After the side cores separate, the center core engines throttle back up to full thrust.

Each of Falcon Heavy’s side cores, or boosters, is equivalent to the first stage of a Falcon 9 rocket with nine Merlin engines. At liftoff, the boosters and the center core all operate at full thrust. Shortly after liftoff, the center core engines are throttled down. After the side cores separate, the center core engines throttle back up. Inside each of Falcon Heavy’s three cores is a cluster of nine Merlin engines. These same engines power Falcon 9, enabling efficiencies that make Falcon Heavy the most cost-effective heavy-lift launch vehicle in the world. With a total of 27 first-stage engines, Falcon Heavy has engine-out capability that no other launch vehicle can match—under most payload scenarios, it can sustain more than one unplanned engine shutdown at any point in flight and still successfully complete its mission.

Interstage

The Falcon vehicles’ interstage, which connects the first and second stages, is a composite structure consisting of an aluminum honeycomb core surrounded by carbon fiber face sheet plies. The interstage is fixed to the forward end of the first-stage tank. The stage separation system is located at the forward end of the interstage and interfaces to the second stage.

Second Stage

Falcon Heavy draws upon Falcon 9’s proven design, which minimizes stage separation events and maximizes reliability. The second-stage Merlin engine, identical to its counterpart on Falcon 9, delivers the rocket’s payload to orbit after the main engines cut off and the first-stage cores separate. The engine can be restarted multiple times to place payloads into a variety of orbits including low Earth, geosynchronous transfer orbit (GTO) and geosynchronous orbit (GSO).

| Falcon 9 | Falcon Heavy | |

Dimensions | ||

Length | 70 m / 230 ft (including both stages, interstage, and fairing) | 70 m / 230 ft (including both stages, interstage, and fairing) |

Diameter | 3.66 m / 12 ft | 12.2 m / 40 ft |

Mass | ||

Propellant Mass | ||

Inert Mass | ||

Gross Mass | 549,054 kg / 1,210,455 lb) | 1,420,788 kg / 3,132,298 lb |

Propellant Mass Fraction |

First Stage

Structure

Type | LOX tank- monococque; Fuel tank- skin and stringer | LOX tank- monococque; Fuel tank- skin and stringer |

Material | Aluminum lithium skin | Aluminum lithium skin |

Propulsion

Engine Designation | Merlin 1D (M1D) | Merlin 1D (M1D) |

Number of Engines | 9 | 27 |

Propellant | Liquid oxygen/kerosene (RP-1) | Liquid oxygen/kerosene (RP-1) |

Average Thrust at Sea Level | 1.710,000 Ibf | 5,130,000 Ibf |

Isp | 285 s (Sea Level) | 285s (Sea Level) |

Chamber Pressure | 1850 psia | 1850 psia |

Nozzle Expansion Ratio | 16 | 16 |

Propellant Feed System | Gas Generator turbopump | Gas Generator turbopump |

Mixture Ratio (O/F) | 2.35 | 2.35 |

Throttling Capability | 43%-100% | 43%-100% |

Restart Capability | Yes, on 3 engines | Yes, on 3 engines per booster |

Tank Pressurization | Heated helium | Heated helium |

Attitude Control

Pitch | Gimbaled engines | Gimbaled engines |

Yaw | Gimbaled engines | Gimbaled engines |

Roll | Gimbaled engines | Gimbaled engines |

Coast attitude control | Nitrogen gas thrusters | Nitrogen gas thrusters |

Staging

Nominal Burn Time | ||

Shutdown Process | Commanded shutdown | Commanded shutdown |

Stage Separation | Pneumatically actuated separation mechanisms | Pneumatically actuated separation mechanisms - three side pusher/one center pusher

|

Second Stage

Structure

Type | LOX tank- monococque | LOX tank- monococque |

Material | Aluminum lithium skin, aluminum domes | Aluminum lithium skin, |

Propulsion

Engine Designation | Merlin Vacuum (Mvac) | Merlin Vacuum (Mvac) |

Number of Engines | 1 | 1 |

Propellant | Liquid oxygen/kerosene (RP-1) | Liquid oxygen/kerosene (RP-1) |

Average Thrust (Total) | 220,500 Ibf | 220,500 Ibf |

Isp, seconds | 346 s | 346 s |

Chamber Pressure | 1764 psia | 1764 psia |

Nozzle Expansion Ratio | 165 | 165 |

Propellant Feed System (e.g., split-expander turbopump) | Gas generator turbopump | Gas generator turbopump |

Mixture Ratio (O/F) | 2.58 | 2.58 |

Throttling Capability | 36% to 100% | 36% to 100% |

Restart Capability | Yes | Yes |

Tank Pressurization (e.g., helium gas, autogenous hydrogen) | Heated helium | Heated helium |

Attitude Control

| Pitch

| Gimbaled engine/nitrogen gas thrusters | Gimbaled engine/nitrogen gas thrusters |

Yaw | Gimbaled engine/nitrogen gas thrusters | Gimbaled engine/nitrogen gas thrusters |

Roll | Nitrogen gas thrusters | Nitrogen gas thrusters |

Coast attitude control | Cold gas thrusters | Cold gas thrusters |

Staging

Nominal Burn Time |

|

|

Shutdown Process | Capable of commanded shutdown or burn to depletion | Capable of commanded shutdown or burn to depletion |

Stage Separation | Payload separation system | Payload separation system |

Avionics

Falcon avionics feature a flight-proven, three-string, fault-tolerant architecture that has been designed to human-rating requirements. Avionics include flight computers, Global Positioning System (GPS) receivers, inertial measurement units, SpaceX-designed and manufactured controllers for vehicle control (propulsion, valve, pressurization, separation, and payload interfaces), a network backbone, and S-band transmitters. The S-band transmitters are used to transmit telemetry and video to the ground, from both the first and second stages, even after stage separation.

The Falcon 9 and Falcon Heavy are equipped with an autonomous flight termination system to limit the potential damage caused by a launch vehicle malfunction. The system terminates the flight of the vehicle automatically if mission rules are violated.

Attitude Control System

Falcon 9 and Falcon Heavy can provide payload pointing and roll control during long-duration coast phases for sun avoidance and thermal control. If requested, the Falcon second stage will point the X-axis of the launch vehicle to a customer-specified attitude and perform a passive thermal control roll of up to ±1.5 deg/sec around the launch vehicle X-axis, held to a local vertical/local horizontal (LVLH) roll attitude accuracy of ±5 deg.

Falcon launch vehicles offer 3-axis attitude control or spin-stabilized separation as a standard service. For inertial separation, the vehicle will point the second stage and payload to the desired LVLH attitude and minimize attitude rates. For spin-stabilized separation, the Falcon launch vehicle will point the second stage and payload to the desired LVLH attitude and initiate a spin about the launch vehicle X-axis at a customer-specified rate dependent upon payload mass properties. Standard pre-separation attitude and rate accuracies are developed as a mission-specific standard service.

Payload Attach Fitting

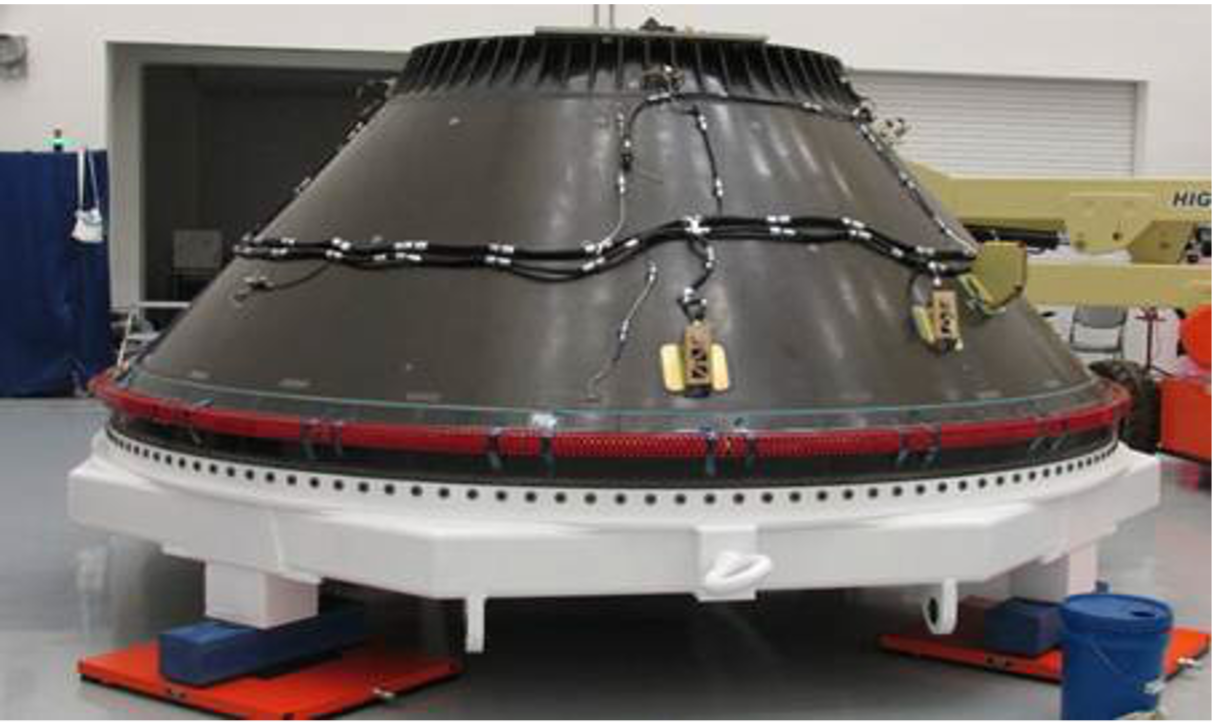

SpaceX Payload Attach Fitting

The payload attach fitting (PAF) converts the diameter of the launch vehicle to a (typical) standard 1575-mm (62.01 in.) bolted interface (Figure above). Payloads should comply with the mass properties limitations given in the figure below. Payloads in excess of the figure can be accommodated as a mission unique service. Payload mass properties should be assessed for all items forward of the payload attach fitting 1575-mm (62.01 in.) bolted interface, including any mission-unique payload adapters and separation systems. Mass property capabilities may be further constrained by mission-unique payload adapters, dispensers or separation systems.

SpaceX can also provide a payload attach fitting with a wider interface. Please contact SpaceX for more details.

Payload Attach Fitting Capability

Payload Fairing

The payload volume indicates the volume that the spacecraft is allowed to move within, without intrusion to the fairing due to its dynamic motions.

Falcon fairing and payload dynamic envelope, meters (feet)

The SpaceX fairing is 5.2 m (17.2 ft) in outer diameter and 13.2 m (43.5 ft) high overall. Fairing structures and dynamics result in a payload dynamic envelope with a maximum diameter of 4.6 m (15.1 ft) and a maximum height of 11 m (36.1 ft). The base of the payload dynamic envelope is defined by the standard 1575-mm interface plane at the forward end of the standard payload attach fitting; any payload adapters required (e.g., to achieve a 937-mm or 1194-mm (36.89 in. or 47.01 in.) interface) will utilize a portion of the payload dynamic envelope.

Length: 13.2 m (43.5 ft)

Primary Diameter: 5.2 m (17.2 ft)

Mass: ?

Sections: 2

Structure: Skin-stringer

Material: Aluminum

The fairing can accommodate one access door in the cylindrical portion as a standard service and eight access doors as a non-standard service. The standard payload fairing door is circular, with a 24 in x 24 in size.

A single through-fairing RF antenna (re-radiation) system is available as a standard service for use during payload antenna testing while on the launch pad. The service is provided for common command and telemetry frequencies. Contact SpaceX for further information on multiple re-radiation systems or non-standard frequencies. Through-fairing RF antenna (re-radiation) systems are not available for using during flight. SpaceX utilizes standard RF antennae locations on the SpaceX fairing and will work to clock the payload accordingly.

Other than remove/install-before-flight items, all processing requiring access to the payload must be completed prior to fairing installation. In the event of a payload anomaly requiring customer access to the payload, the standard concept of operations for Falcon vehicles is to return the launch vehicle to the hangar and remove the fairing. Access doors are not designed for emergency access into the payload fairing once the launch vehicle is on the pad.

Combinations of acoustic surfaces are used inside the payload fairing to help achieve the acoustic environments specified below.