Proton

Production and Launch Operations

Launch Facilities

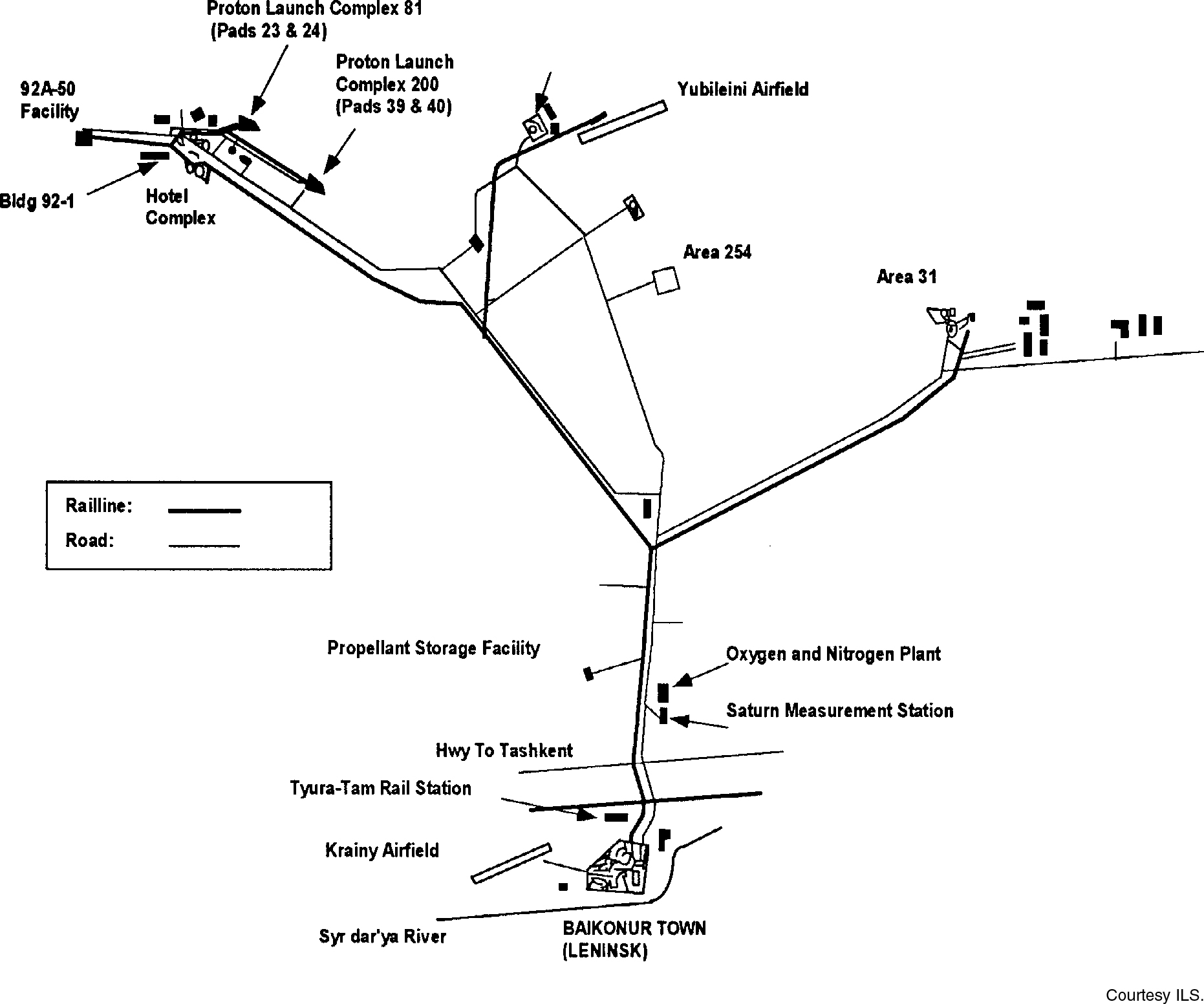

Baikonur Launch Site Layout

Proton Launch Zone, Area 81

Proton Preparation at the Horizontal Assembly Facility

Rail Transport to the Launch Pad

View of Proton Launch Site Layout

Production

Proton is produced at the Khrunichev factory in Moscow. The Proton stages and Block DM upper stage are manufactured and assembled at the factory, then shipped by rail to Baikonur for integration. The Khrunichev factory has suffered significant budgetary and personnel cutbacks as a result of the end of the SS-19 missile program, which had been one of the major products of the facility. Fortunately, commercialization of the Proton has been successful and the Proton production line is the only missile or launch vehicle line in the former Soviet Union to be operating near full capacity. Unlike other launch vehicles, Proton launch rates are still comparable to their peak during the Soviet era. The following organizations produce elements of the Proton.

RSC Energia | Block DM fourth stage |

NPO Energomash | First-stage engines |

KB Khimavtomatiki | Second- and third-stage engines |

IKP Mars/NIIAP | Guidance and control systems |

SAAB Aerospace | Commercial payload separation systems |

A Proton M is assembled in one of the Khrunichev factory buildings.

Breeze M Upper Stage

Launch Operations—Baikonur

Proton is launched from the Baikonur Cosmodrome, in the Republic of Kazakhstan east of the Aral Sea. For general information on Baikonur, please see the Spaceports chapter. Spacecraft can arrive at the Yubileini Airfield in the north-central section of the cosmodrome. The airfield is a Category 3 airfield, capable of handling very large aircraft. In fact it was built for landings of the Soviet space shuttle, and of its An-225 carrier aircraft—the largest aircraft in the world. Spacecraft are then transported to Area 92 on the western arm of the Cosmodrome, where the spacecraft processing facilities, Proton launch pads, and customer housing are located.

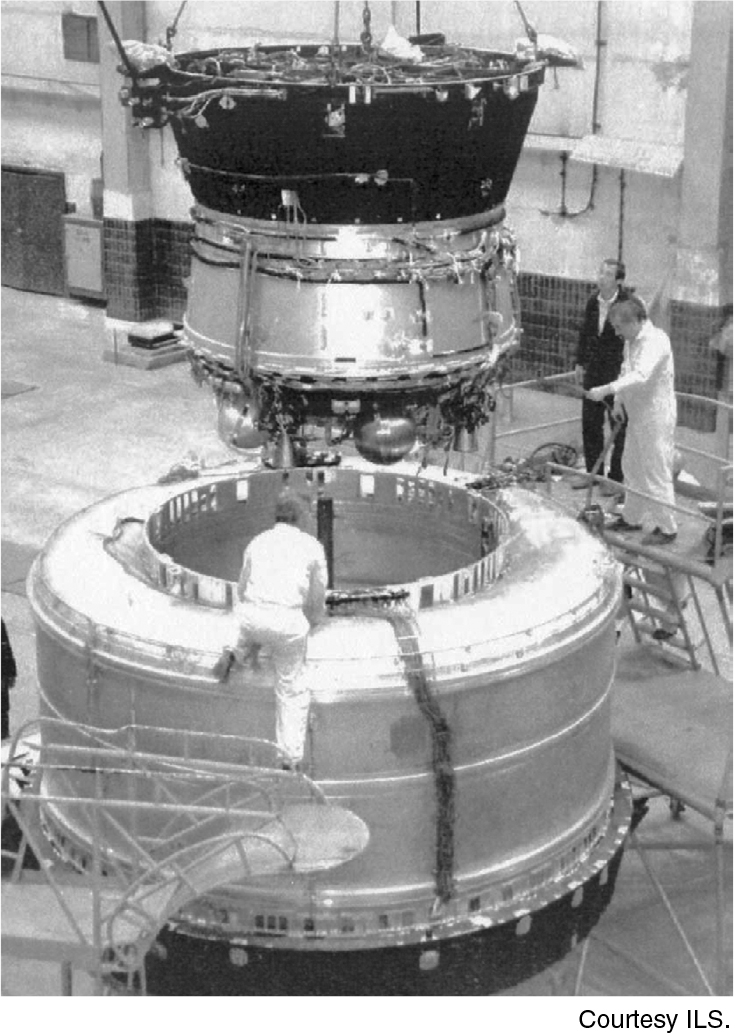

Proton stage assembly, vehicle integration, and prelaunch testing are performed in Buildings 92-1 and 92A-50. In the long assembly hall, first-stage external fuel tanks are integrated onto the first-stage core on a special handling fixture that rotates the entire stage for easy access. The vehicle is fully integrated in a horizontal position on rail trolleys. Spacecraft processing takes place in one of two areas. Early commercial launches used Area 31, Building 40D for nonhazardous processing, and Building 44 for hazardous processing. Area 31 is on the eastern arm of the cosmodrome and is also used for Soyuz and Zenit processing. Current and future commercial payloads will use Building 92A-50, which is much closer to the Proton launch complexes and customer hotels and has been upgraded to Western standards. Area 31 is still available if required, and is also used for fueling the Block DM upper stage. The space vehicle processing facility (SVPF) is in one small section of Building 92A-50, and consists of a long row of halls connected end to end. Overhead cranes are available, and a set of rail tracks running the length of the building can be used to move spacecraft. The spacecraft in its container is delivered to Hall 102 for reception, unpacking, and storage. Once unpacked, it is moved through Hall 101 to Hall 103 at the opposite end of the building. Hall 103A is used for hazardous operations, including fuel loading. Once fueled and checked out, the spacecraft is returned to Hall 101, for integration onto the payload adapter, mating with the fueled upper stage, and encapsulation into the payload fairing. It is then rotated into a horizontal position and mounted on a rail car for delivery either to Building 92-1, or to Hall 111 of Building 92A-50.

The Proton Launch Vehicle Processing Rooms in Buildings 92-1 and 92A-50 are approximately 30 m wide×19 m long×23 m high (100×390×75 ft), and contain three rail tracks upon which Protons can be transported. Assembly and integration of the Proton launch vehicle stages are carried out with the vehicle in a horizontal position. The first stage’s core oxidizer tank and six fuel tank–engine assemblies are transported to Baikonur separately. Assembly of the first stage is accomplished by placing the core tank in a fixture that rotates the tank about its longitudinal axis. After the first fuel tank–engine assembly is attached from underneath the horizontal oxidizer tank, the whole assembly is rotated one-sixth of a revolution to allow for the integration of the next fuel tank–engine module. The process is repeated until all six fuel tank–engine assemblies are attached. Following completion of its assembly, the first stage is moved by crane to the assembly integration erector trolley, where it is mated to the second and third stages. The integrated vehicle is then mated to the upper stage and payload assembly. The assembled Proton then undergoes integration tests. Up to three Proton launch vehicles can be processed simultaneously in each building, and the assembly buildings can accommodate as many as six boosters at one time. Each vehicle requires two weeks for assembly, followed by one week of end-to-end tests. However, the process has been done in as little as nine days for especially urgent missions. Once fully prepared, the Proton is lifted onto a transport-erection rail car using overhead bridge cranes, and transported to the launch pad. A thermal control rail car is available to maintain required environments inside the fairing. Once at the launch pad, the erector lifts the Proton into the vertical position and mounts it on the launch pad.

Protons are launched from two launch complexes at Baikonur, Launch Complex 81 and Launch Complex 200. Each complex has two pads. Launch Complex 81 was built first, in the 1960s and then deactivated in the late 1970s when the pads reached the end of their initial service life. One of the pads, Pad 23 (LC 81 Left) was refurbished and reactivated in 1989. It also became the primary commercial launch pad in the 1990s. The second pad, Pad 24 (LC 81 Right) was repaired and refurbished in the late 1990s in response to increasing commercial demand for Proton K, and the need for a pad designed to launch the new Proton M. Krunichev spent 260 million rubles ($8 million) renovating Pad 24 using funding from its commercial revenues. It will be the primary pad for Proton M. Launch Complex 200 was built in the late 1970s, apparently to handle planned versions of the Proton with a new fluorine/ammonia upper stage powered by the RD-301 engine. The advanced upper stage never flew, probably a result, in part, of engineering and safety problems associated with the propellants. LC-200 includes Pad 39 (LC 200 Left) and Pad 40 (LC-200 Right). Pad 39 is used for Russian government and commercial missions, and Pad 40 is inactive.

Each pad includes a launch mount and a mobile service tower mounted on railway tracks for access to the vehicle and payload once the rocket is erected. In surge mode, two Protons can be launched from the same pad in about 21 days (Protons have been launched from the same pad in as little as 14 days). As a result of having four available pads, Protons have occasionally been launched as little as four days apart. It takes 4 h to erect and install Proton on the launch pad; typically, this takes place three to five days before launch. Preliftoff maintenance and service operations are carried out with the aid of the mobile service tower. No cable or umbilical tower is incorporated into the launch complex. Many of the services that would be provided by such an umbilical tower are provided by the mobile service tower. Other functions, including fuel loading, are performed by a special servicing mechanism that connects to the Proton at the base of the first stage. All fuel and compressed gas loading operations, including the attaching and removing of connections, are fully automated. The propellant for the vehicle is stored near the launch pad in underground bunkers. The Proton launch complex has undergone evolutionary modifications brought about by changes in the booster's applications. These upgrades include a cryogenic LOX handling system to support the Block DM, a new compressed gas delivery system, and improved on-pad payload thermal control systems.

Approximately 8 h before liftoff, the payload’s onboard systems are checked out, and the satellite’s readiness for launch is confirmed by checking its telemetry data. Individual safety devices are removed no less than 30 min before launch. Recharging of the onboard chemical batteries is stopped 1.5 h before launch, although trickle charging can continue until 5 min before liftoff. Launch pad personnel are evacuated from the pad area 1.5 h before launch. Shortly thereafter, the mobile service tower is rolled back to a safe distance from the launch pad. Launch go-ahead must be provided by the payload customer no less than 2 min before launch. If a launch scrub occurs, it requires 6–8 h to defuel the booster and an additional 4 h to lower it to a horizontal position for rollback to the horizontal assembly building.

Launch is controlled from a command center located about 1.5 km (1 mi) from the launch complex. At the moment of liftoff, the launch pad servicing mechanism rises with the launch vehicle, tracking the vehicle's movement for the first few fractions of a second. After approximately 20mm of motion, this mechanism is separated and withdrawn by a pneumatic actuator and secured behind an armored steel fire wall cover. This steel cover then helps form part of the launch pad flame deflector.

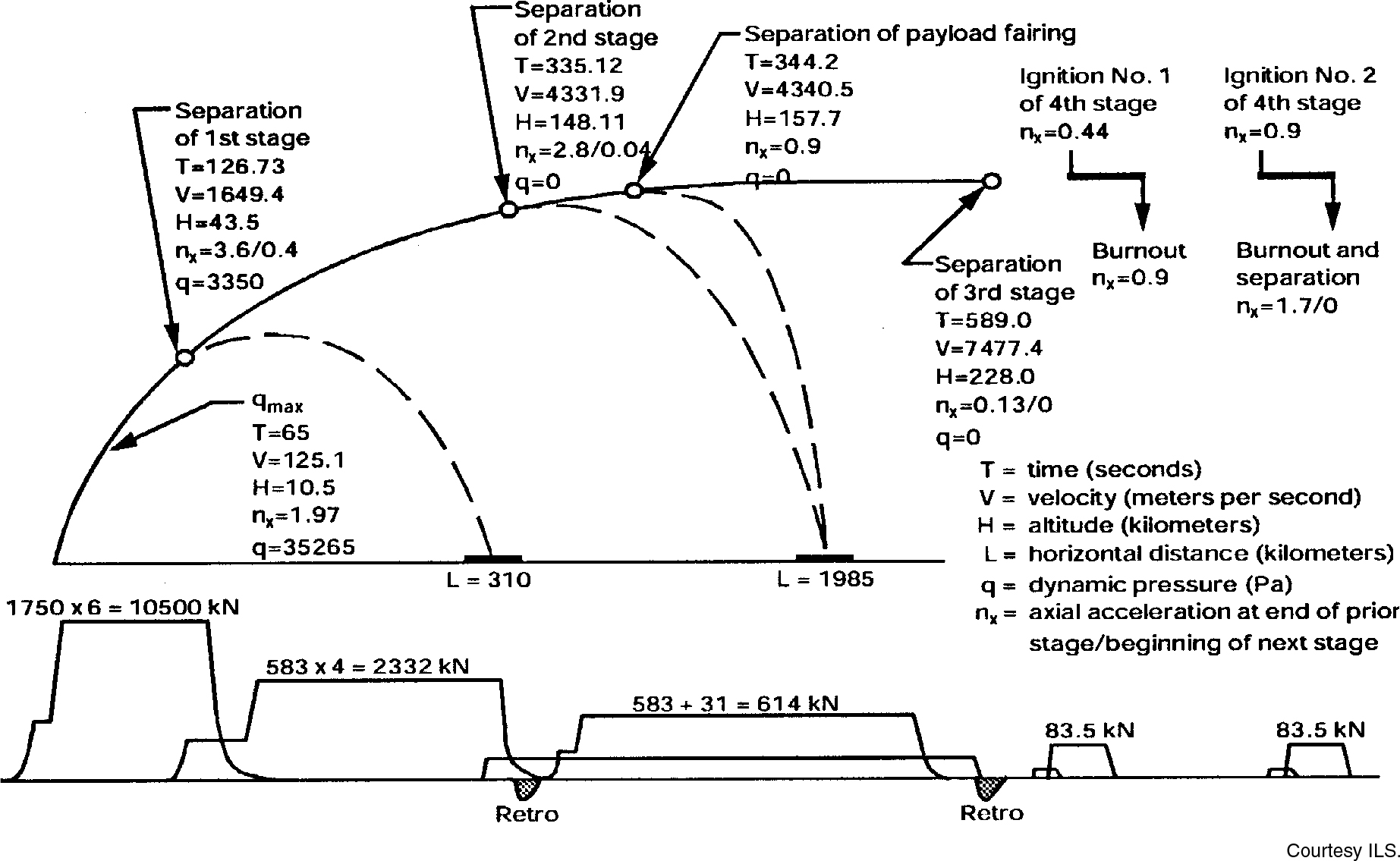

Flight Sequence

Event sequence is shown for Proton K/Block DM. The event sequence for Proton M/Breeze M is essentially similar through third stage shutdown. The timeline for Breeze M flight depends on mission requirements.

Event Sequence for Proton Launch to GTO with Block DM Upper Stage | |

Event | Time, s |

Stage 1 ignition - 0 up to 50% thrust | -160 |

Begin Stage 1 throttle up to 100°% | -0.00 |

Stage 1 thrust at 100% | 0.10 |

Lift-off | 0.17 |

Stage 2 ignition | 12240 |

Stage 1 / 2 separation | 126.60 |

Stage 3 vernier engine ignition | 332.0 |

Stage 2 engine shutdown | 334.40 |

Stage 2 / 3 separation | 335.10 |

Stage 3 main engine ignition | 337.50 |

Payload fairing jettison | 344.20 |

Stage 3 main engine shutdown | 577.10 |

Stage 3 vernier engine shutdown | 589.00 |

Stage 3 / upper stage separation | 589.10 |

Block DM upper adapter jettison | 637.00 |

SOZ unit first settling burn | 5437.00 |

Block DM main-engine first burn | 5732.00 |

SOZ unit shutdown | 5737.00 |

SOZ unit second burn | 24,800.00 |

Block DM main-engine second burn | 25,105.00 |

SOZ unit shutdown | 25,105.00 |

Payload deployment | 25,324.00 |