Proton

Proton M/Breeze M

Proton M/Breeze M | |

Height | 56.2 – 58.2 m (184.4-190.9 ft) |

Gross Liftoff Mass | 705 t (1554 klbm) |

Thrust at Liftoff | 10.5 MN (2350 klbf) |

Stages

The Proton launch vehicle consists of three core stages for injection into low orbit. An optional fourth stage can be added for higher orbits or to change inclination. The first three stages are fueled by N2O4/UDMH. Proton was originally designed to serve as either a space launch vehicle or a heavy ICBM, and therefore storable propellants were chosen to permit Proton to be held on standby for a long period of time and still launch rapidly.

Proton is constructed of an aluminum alloy and is covered by an external thermal finishing paint. Propellant tanks are internally coated with an anticorrosive coating. The oxidizer also has a passive abator mixed into it to reduce its corrosiveness.

The Proton first stage consists of a large central core oxidizer tank surrounded by six smaller fuel tanks. These are easily mistaken for strap-on boosters, but in fact they are an integral part of the first stage and do not separate. This distinctive design stems from early requirements for transporting Proton. The vehicle stages had to be manufactured at a central factory, then shipped by rail to the launch sites. The maximum length and diameter of the components were therefore limited by existing railway tunnels and other rail infrastructure. However, performance requirements dictated that first stage would exceed these dimensions, thus requiring that it be manufactured as more than one element. Two designs were considered. The first consisted of two cylindrical assemblies with similar length and diameter. The fuel tank and integrated engine compartment could be shipped as one element, and the separate oxidizer tank would be stacked on top of it at the launch site to form the first stage. The second design consisted of a large central oxidizer tank, with several smaller fuel tanks that could be strapped on at the launch site. While this design was somewhat heavier and more complex, it resulted in a much stiffer structure. The total height of the rocket would also be shorter, thus simplifying launch infrastructure. These considerations led to the selection of the second configuration. In the final design, six strap-on tanks were chosen, each with one RD-253 engine. The strap-on assemblies are integrated with the core tank on a special rotating assembly fixture at the launch site.

The first-stage RD-253 engines, developed between 1961 and 1965, use a staged-combustion cycle. After the fuel goes through the pumps, all of the oxidizer and a small portion of the fuel enters the gas generator attached to the turbine housing. The remaining fuel is delivered to the regenerative cooling channels of the chamber. The turbine exhaust gas is delivered through to the combustion chamber, where it is burned with the fuel that has passed through the chamber cooling channels. For reliable cooling of the chamber, its fire wall is protected by a refractory ceramic coating and a gas–liquid film formed by delivery of a portion of the fuel component from the cooling channel to the wall through openings. The maximum fuel pressure in the main lines of the engine reaches 400 atm. The use of self-igniting hypergolic propellant eliminates the need for an ignition system. The engine is fired and cut off by nine pyrotechnic valves. A regulator and choke operating from electric drives are installed in the main lines to control the thrust and ratio of fuel and oxidizer flow rates during flight of the engine. Supercharging assemblies produce gases for pressurizing the rocket fuel tanks. The extensive application of welding ensures the structural integrity of the rocket engine. Heat shielding around the engines protect the engine assemblies against the reaction gas jet influence. The gimbal assemblies, which attach the engine to the rocket, provide for the rotation of the main thrust chambers in a plane parallel to the rocket’s longitudinal axis so that flight direction and attitude of the booster can be controlled. The RD-253 engines have been uprated first to 102% and then later to 107% of rated thrust by modifying the propellant flow control valves, and are now designated by the model number RD-259. This modification was first used as a mission-specific upgrade on the Proton K that launched the Mir space station in 1986. It was later incorporated into standard production vehicles. Through 1998, 65 flights used the 102% thrust level. The 107% uprated engines were introduced in 1995 and are standard on Proton K and M vehicles.

The second and third stages both have tanks using common bulkhead domes and are powered by different versions of the RD-0210 engine. Four single high-pressure combustion chamber RD-0210 engines are mounted on the second stage. Three of these are the RD-465/RD-0210 variant, while the fourth is an RD-468/RD-0211 which includes a gas generator for tank pressurization. The third stage uses a single RD-473/RD-0212 variant of the basic RD-0210 engine, which includes a fixed central RD-0213 version of the RD-0210 engine plus four conventional vernier thrust chambers designated RD-0214. The third stage cannot be restarted or throttled, but, like all stages on Proton, the burn time can be varied according to the mission. In response to two failures, the RD-0210 engines were upgraded in 2000 to reduce the risk of fire and to filter potential contaminants in the propellant feed lines.

Block DM

The Block DM fourth stage is used to transfer payloads from LEO into GEO or interplanetary trajectories. It includes a spherical LOX tank and a toroidal kerosene tank that circles the single 11D58M main engine. The tanks are connected with a truss structure. To provide long operational lifetime in orbit before the LOX boils away, the oxygen tank is covered with ML1 “superinsulation” and thermally isolated from the rest of the stage using inserts in the structural connections that have low thermal conductivity. The standard Block DM avionics are housed in a pressurized, toroidal instrumentation compartment at the top of the stage. The alternative Block D stage lacks the instrumentation compartment and is instead controlled by its payload. The Block DM stage can function for 24 h or more on orbit, and is capable of five to seven restarts, allowing complex orbital maneuvers. The main engine can burn either conventional kerosene or a synthetic hydrocarbon fuel called syntin. Syntin is slightly denser and provides slightly better performance, but is more expensive than kerosene. When integrated on the launch vehicle, the Block DM is contained inside a cylindrical skin-stringer load-bearing shroud that is jettisoned before Block DM ignition. The shroud is divided into two sections, referred to as the lower adapter and middle adapter. Combined, the mass of these elements is about 850–900 kg (1900–2000 lbm), which is not included in the mass of the stage reported in the table below.

Changes for the Proton M consist of a number of minor structural enhancements with no fundamental changes to the first three stages plus the replacement of the original Proton K analog avionics system with a state-of-the-art digital GNC system. Stage inert weights are reduced using improved manufacturing techniques, minor design changes, and a reduction in avionics mass. The forward section of the second stage is strengthened to accommodate greater loads from heavier payloads and larger fairings. The propellant lines for the first and second stages are redesigned to reduce propellant residuals by 50%. This provides a slight performance improvement but is primarily intended to reduce the amount of toxic propellant that remains in the tanks when the jettisoned stages impact in the designated drop zones. To this end, a propellant purge system has also been added to expel propellants into the upper atmosphere before impact.

The Breeze M upper stage is a modified version of the Breeze KM upper stage used on Rockot. It consists of two separate components. The cylindrical core section, which is very similar to the Breeze KM, includes a single main engine, reaction control system engines, propellant tanks, and an avionics bay. Surrounding the core section is a toroidal auxiliary propellant tank that carries additional propellant. This tank carries the majority of the Breeze M propellant, and can be jettisoned in flight once the propellant is exhausted.

Breeze M Upper Stage

Stage 1 | Stage 2 | Stage 3 | Stage 4 Block DM | Stage 4 Breeze-M | |

Dimensions | |||||

Length | 21.2 m (69.5 ft) | with interstage: 17.1 m (55.9 ft) | 6.9 m (22.6 ft) | 6.3 m (20.7 ft) without payload adapter | 2.8 m (9.2 ft) |

Diameter | Core: 4.1 m (13.4 ft) | 4.1 m (13.4 ft) | 4.1 m (13.5 ft) | 3.7 m (12.1 ft) | 4 m (13 ft) |

Mass | |||||

Propellant Mass | 419.4 t (924.4 klbm) | 156.1 t (344.2 klbm) | 46.6 t (102.6 klbm) | 15,050 kg (33,180 lbm) | Core tank: 5200 kg (11,500 lbm) |

Inert Mass | Proton K: 31.0 t (68.3 klbm) | Proton K: 11.7 t (25.8 klbm) | Proton K: 4185 kg (9225 lbm) | With equipment bay: 2440 kg (5380 lbm) Without equipment bay: 1700 kg (3750 lbm) | 2370 kg (5225 lbm) |

Gross Mass | 450 t (993 klbm) | Proton K: 167.8 t (369.9 klbm) | 50.6 t (112 klbm) | 16,300-17,490 kg (35,935-38,560 lbm) | 22,170 kg (48,865 lbm) |

Propellant Mass Fraction | 0.93 | 0.93 | 0.92 | 0.86-0.90 | 0.89 |

Structure | |||||

Type | Skin-stringer | Skin-stringer | Skin-stringer | Monocoque, truss | Monocoque |

Material | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum composite |

Propulsion | |||||

Engine Designation | RD-259 | RD-0210 (3 RD-465 and 1 RD-468 version) | RD-0210 (RD-473 version) | 11D58M / RD-58M | S5.98M main engine (Khimavtomatiki Design Bureau) 11D458 verniers |

Number of Engines | 6 | 4 | 1 core engine + 1 vernier engine with 4 nozzles | 1 | 1 main engine + 4 vernier engines |

Propellant | N2O4/UDMH | N2O4/UDMH | N2O4/UDMH | LOX/kerosene or syntin | N2O4/UDMH |

Average Thrust (total) | Sea level: 9.5 MN (2.1 Mlbf) | Vacuum: 2.33 MN (524 klbf) | Vacuum: Main engine: 583 kN (131 klbf) | Syntin: 86.3 kN (19.4 klbf) | Main engine: 19.62 kN (4410 lbf) |

Isp | Sea level: 285 s | Vacuum: 326.5 s | Vacuum: 326.5 s | Syntin: 361 s | Main engine: 325.5 s |

Chamber Pressure | 147 bar (2130 psi) | 147 bar (2130 psi) | 147 bar (2130 psi) | Syntin: 79.4 bar (1152 psi) | 97 bar (1405 psi) |

Nozzle Expansion Ratio | 26:1 | 81.3:1 | 81.3:1 | 189.1:1 | 153.8:1 |

Propellant Feed System | Staged-combustion turbopump | Staged-combustion turbopump | Staged-combustion turbopump | Staged-combustion turbopump | Main engine: closed-cycle turbopump |

Mixture Ratio (O/F) | 2.69:1 | 2:0:1 | 2:0:1 | 2.6:1 | 2:0:1 |

Throttling Capability | 40% before liftoff, 100-107% during flight | 100% only | 100% only | 100% only | 100% only |

Restart Capability | No | No | No | Up to 7 restarts | Up to 8 total starts (5 demonstrated) |

Tank Pressurization | Gas Generator | Gas Generator | Gas Generator | Stored pressurized gas | Nitrogen |

Attitude control | |||||

Pitch, Yaw, | Gimbal 6 nozzles | Gimbal 4 engine nozzles | 4 verniers | Nozzle gimbal ± 3 deg | Nozzle gimbal |

Roll | Gimbal 6 nozzles | Gimbal 4 engine nozzles | 4 verniers | Rotating nozzle using turbine exhaust gas | 12 ACS thrusters, 13.3 N (3.0 lbf) each |

Staging | |||||

Nominal Burn Time | 120 s | 210 s | 230 s | 680 s | 3000 s |

Shutdown Process | Burn to depletion | Burn to depletion | Predetermined velocity | Predetermined velocity | Command shutdown |

Stage Separation | Stage 2 ignition | 6 solid retro-rockets | Retro-rockets | ACS/Spring ejection of payload | ACS/Spring ejection of payload |

Attitude Control System

On the first stage, each of the six RD-259 engines can gimbal in a single plane tangential to the stage’s circumference. Thus, all six engines together provide full yaw, pitch, and roll control. Second-stage control is achieved by gimbaling the four RD-0210 engines. The third stage is controlled by four vernier rocket engines spaced around the single fixed RD-0210.

During Block DM stage burns, the 11D58M main engine gimbal provides pitch and yaw control, and turbopump bleed gas is used for roll control. The Block DM stage also has two sets of independent SOZ (micro) thruster units for three-axis attitude control during coast phases and for propellant settling before main engine ignition. These are fueled by small tanks of N2O4/UDMH and contain four thrusters each, ranging in thrust from about 25 N (5.5 lbf) for the axial propellant settling thrusters to 100 N (22.5 lbf) for the yaw thrusters. The SOZ units can be jettisoned after the main engine ignites for its final burn.

The Breeze M stage has a gimbaled main engine for pitch and yaw control, and 12 ACS thrusters with a thrust level of 13.3 N (3.0 lbf) each for roll control during main engine burns and three-axis attitude control during nonpropulsive phases of flight.

Avionics

The Proton third stage is equipped with a triple-string, voting, closed-loop guidance system for the control of the first three stages. Navigation data are collected from distributed inertial reference platforms. The Proton K control system is analog and based on 1960s-era electronics. The Proton M has modern digital flight control systems, which will simplify testing and flight algorithm loading and will allow more complex ascent flight profiles.

The Block DM has an independent guidance, navigation, and control system, which is contained in a pressurized toroidal compartment above the oxygen tank. The guidance system is a triple-string, voting, digital system that can be commanded from the ground. Limitations of the Block DM gyro platform prevent the stage from rotating more than 180 deg from a given reference orientation.

The Breeze M has an onboard digital computer, three-axis IMU and GLONASS and GPS navigation systems. It is capable of either three-axis-stabilized orientation or spin-stabilized mode. The GNC system was developed using modern 1990s-era hardware and software and architectures. It is a multiple redundancy system, which can be commanded from the ground and can retarget and optimize its trajectory in flight. It can be programmed to complete complex maneuvers to meet spacecraft pointing, thermal control, and separation requirements.

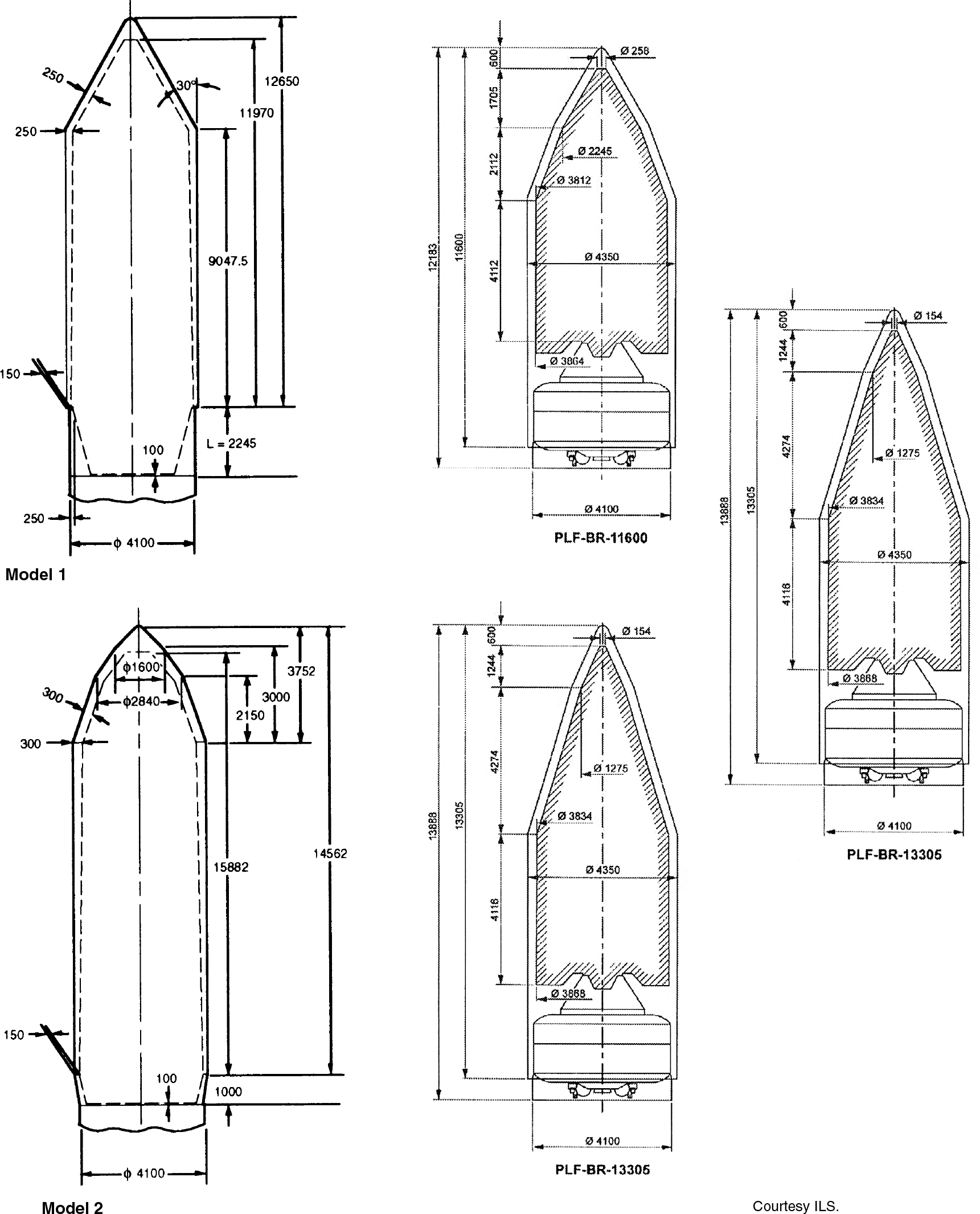

Payload Fairing

Multiple payload fairings are available for the Proton. All fairings are made up of two half shells. Additional acoustic blanket layers can be attached to the inside of the payload shroud if required. Proton payload fairings incorporate active air and liquid cooling and heating systems to maintain spacecraft prelaunch thermal control, regardless of ambient conditions at the launch site. The payload fairing is attached to the third stage in the three-stage or Breeze M configurations or the Block DM cylindrical shroud. Because of hardware impact zone constraints, the Proton payload fairing must be separated either approximately 180 s into flight at an altitude of 110 km (59 nmi), or approximately 350 s into flight, immediately following second-stage separation, at an altitude of 200 km (108 nmi).

Models 1 and 2 | Breeze M | |

Length | 14.9 m (48.9 ft) | 11.6 m (38.1 ft)—BR-11600 |

Primary Diameter | 4.4 m (14.4 ft) | 4.35 m (14.3 ft) |

Mass | ? | ? |

Sections | 2 | 2 |

Structure | Skin-stringer | Monocoque sandwich |

Material | Aluminum | Composite |