Verification & Validation for High Temperature Material Modeling & Applications – Online Short Course (Started 17 Feb 2026) 17 February 2026 - 12 March 2026 Online

- From 17 February – 12 March 2026 (4 Weeks, 8 Classes, 16 Total Hours)

- Every Tuesday and Thursday at 1–3 p.m. Eastern Time (all sessions will be recorded and available for replay; course notes will be available for download)

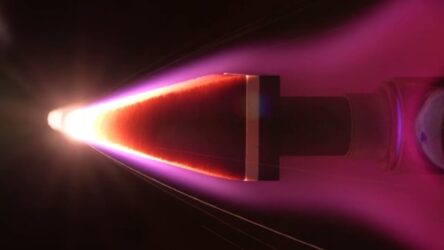

- This new unique course taught by leading experts from AIAA’s Thermophysics Technical Committee covers the behavior and test methods for high temperature materials, which are critical for hypersonic vehicle design.

- All students will receive an AIAA Certificate of Completion at the end of the course.

OVERVIEW

High temperature materials are critical for hypersonic vehicle design. The behavior of these materials, whether they are traditional ablative thermal protection systems (TPS) or more shape stable systems, must be understood for proper vehicle design. This course introduces the analytical and test methods utilized to capture this behavior. The link between test measurements, analytical model verification and validation, and uncertainty quantification is explored from basic property measurements to subscale arc-jet tests.

KEY TOPICS

- Introduction to high temperature materials modeling and testing

- Material microstructure for common materials. Microstructure-resolved properties and mesoscale physics.

- Macroscale modeling of common materials.

- Experimental methods – how to set up a successful test and a comparison of common test methods

- Material properties measurements – introduction to common test methods and how this data is utilized in analytical models

- Heated material test methods – a comparison of test methods to rapidly heat materials along with pros and cons for each type

- Analytical model verification and validation – an introduction to the methods used to validate or verify analytical models with collected test data

- Uncertainty Quantification – an introduction into understanding and quantifying analytical and test measurement uncertainty.

- [Detailed outline below]

This course is relevant to those working in the high temperature materials world associated with space, reentry, and hypersonics. The intended audience is graduate students or working professionals interested in the prediction and testing of high temperature materials. Students should have a background in engineering, materials science, or both. Course materials will delve into graduate level materials but at an introductory level providing the basic equations and theory but do not require any specific pre-requisites. The instructors enjoy burning up materials and trying to figure out stuff about it, and they hope to share that passion through the class!

COURSE FEES (Sign-In To Register) It’s not too late to register! Catch up by watching recorded lectures.

– AIAA Member Price: $945 USD

– Non-Member Price: $1145 USD

– AIAA Student Member Price: $595 USD

CLASSROOM HOURS / CEUs: 16 classroom hours / 1.6 CEU/PDH

Cancellation Policy: A refund less a $50.00 cancellation fee will be assessed for all cancellations made in writing prior to 5 days before the start of the event. After that time, no refunds will be provided.

Contact: Please contact Lisa Le or Customer Service if you have any questions about the course or group discounts.

OUTLINE

Class 1: Introduction to high temperature materials modeling and testing

- What is it and why is it important

- Brief history of high-speed flight

- Recent advancements and the relationship of Temperature α Velocity3

- Common materials used and why, Categories: shape stable vs. ablative

- Ablation model diagram with all mass, momentum, and energy balances for the surface

- Brief history of ablation modeling

- Brief history of materials testing

- Show engineering cycle of analysis to test.

- No “one model fits all” because materials behave differently. Discuss pros and cons to current analytical methods

- Define microscale and mesoscale modeling and show link – details in upcoming Classes

- Show test levels (properties, small samples, to subsystems) and show link to modeling

Class 2: Introduction to experimental methods, how to set up a successful test

- High Temperature Experimental Methods and Facilities

- Why test?

- To understand material behavior (new learning)

- To validate analytical modeling (anchor existing information)

- What to test?

- Testing objectives – defining clear test goals

- Understand what you need to advance your understanding

- Where to test?

- Facility categories or types – figures and tables of major facilities.

- Alt/mach, shear/q cold wall, etc.

- How to start? (i.e. from a trajectory or use case)

- A walkthrough of an “escalation” approach, increasing the similarity of your test to your end application environment as you go

- Thermophysical Properties

- Aerothermal Screening – more limitations

- Downselection Methodology (i.e. scoring)

- Ground Testing – fewer limitations

- Post-Test

- Test limitations (Ground Test does not equal Flight)

- Ground to flight extrapolation theory

- What data to collect? How to tie measurements to test goals.

- Equilibrium versus non-equilibrium, char front, measurement at high temperature, etc.

Class 3: Thermophysical property measurements, aerothermal screening

- Discussion on thermophysical properties, NDE, and lab scale evaluations (emphasis on high temperature techniques)

- Facility table – places to get high temperature property testing

- TGA – overview

- DSC – overview

- Emissivity – overview

- CTE – overview

- Thermal conductivity – overview

- Micro-CT – overview

- FTIR – overview

- Thermomechanical – overview

- Specialty testing – permeability, pore pressure evolution, etc.

- Coupon to vehicle testing, overview – Pros and cons as you go up in test complexity.

- Oxy-Torch – Pros/Cons

- Arc – huels, pros/cons

- Arc – segmented, pros/cons

- Plasma jet – pros/cons

- HVOF – pros/cons

- Burner Rig/blowdown – pros/cons

- HTT – pros/cons

- Discussion on Aerothermal Screening

- What you can realistically achieve in a low-cost, high-throughput facility – a brief comparison

- Where do you compromise? (e.g. heating method – LHMEL vs plasma or quartz lamp, combustion products in HVOF and burner rigs?)

- “Easier” instrumentation – pyrometry, thermocouples, radiography, etc.

- Downselection Methodology

- How do I weigh what is important?

- How do my models’ sensitivity to each parameter play into this?

- Construct a scoring matrix

- Reconnect this to the development of objectives (the first Class) – in other words, your objectives should be ready to support this step

Class 4: Ground testing and post-test analysis

- Ground Testing

- Additional benefits of a larger (or more capable) facility. A brief comparison list.

- Overview of more measurement techniques: calorimetry, gas composition, shear, etc.

- Ground-to-Flight extrapolation theory (and weaknesses)

- Pre-test measurements

- Weight, size, blue light scan, CT, etc.

- CFD – pros/cons, why to model before test.

- In-test measurements

- Facility data, high speed video, TCs, Pyrometry, IR imagery, gas composition, photogrammetry, etc.

- Post-test measurements

- Destructive vs. non-destructive, weight, size, CT, etc.

- Microscopy, char depth, density gradients, CFD – post-test pros/cons

- Post-test Analysis

- My test is complete! Now what?

- Test uncertainty

- My model doesn’t match my test – unexpected results

- Challenging assumptions – 1D heating or not

- Challenging assumptions – equilibrium or not

- Identifying holes – where the model is ‘valid’ and not.

- Same conditions but different results. Possible causes

- Extrapolation – increases to uncertainty and error.

- Ground Testing shouldn’t be pass/fail!!!

- Post-test NDE for materials understanding (i.e. microscopy, CT/radiography, UT, etc.)

- Model predictions – pre vs. post test

- How to adjust a model

- Common adjustments

- Model limitations

- Empirical data fits

- Small sample size for data fits

Class 5: Macroscale modeling of common materials

- Thermal Protection System (TPS) definition and use

- Reusable vs. Single use

- Shape stable vs. shape changing

- Active vs. passive TPS

- Overview – single use TPS phenomena

- Pyrolysis modeling methods

- Recession modeling methods

- Chemical/Decomposition removal

- Mechanical removal

- Introduction to common software tools

- How test data is used in modeling

- Material properties

- Screening Tests

- Validation Tests (arc jet or similar)

Class 6: Material microstructures, microstructure-resolved properties and mesoscale physics

- Module 1: Material Microstructure

- Objective: Set the physical stage for why microscale modeling is essential.

- Microstructure of carbon composites: (15 minutes)

- Carbon–carbon and carbon–phenolic: tow bundles, voids, matrix

- Anisotropy, porosity, and surface roughness introduced by ablative recession

- Microstructure of ultra-high temperature ceramics: (15 minutes)

- Oxide layer growth, liquid diffusion

- Impurities and defects

- Relevance to hypersonic conditions (10 minutes)

- Multi-scale analysis and modeling (10 minutes)

- Molecular beam experiments and finite-rate gas-surface chemistry (10 minutes)

- Microstructure of carbon composites: (15 minutes)

- Module 2: Microstructure-resolved properties and mesoscale physics

- Objective: Simulate the true mesoscale surface structure and its effect on gas flow and ablation.

- Use of tomography to obtain realistic microstructures (5 minutes)

- Generating effective properties from the microstructures (25 minutes)

- Property tensor

- Property distribution functions

- Uncertainties and variabilities

- Coupled fluid-material evolution simulations at the microscale (15 minutes)

- Diffusion vs reaction-limited regimes

- Needling vs thinning

- Oxidation vs sublimation

- When does the microstructure play a role

- Discussion of open-source tools (10 minutes)

- Summary (5 minutes)

Class 7 and 8: Introduction to Uncertainty Quantification (UQ). Understanding and quantifying analytical and test uncertainty

- Introduction to UQ and review of basic concepts (1 hour)

- The need for UQ in high-temperature materials research

- Opportunities and challenges

- Overview of state-of-the-art methods in high-temperature materials research

- Random variables and probability distributions

- Random vectors and processes

- Forward propagation of uncertainty and sensitivity analysis (1 hour)

- Monte Carlo sampling and estimators

- Local sensitivity analysis methods

- Global sensitivity analysis methods

- Bayesian inference (1 hour)

- Introduction to Bayes’ theorem

- The role of prior distributions

- Likelihood functions and noise modeling

- Posterior sampling algorithms and convergence diagnostics

- Review of state-of-the-art algorithms and recap (1 hour)

COURSE DELIVERY AND MATERIALS

- The course lectures will be delivered via Zoom. Access to the Zoom classroom will be provided to registrants near to the course start date.

- All sessions will be available on-demand within 1-2 days of the lecture. Once available, you can stream the replay video anytime, 24/7.

- All slides will be available for download after each lecture. No part of these materials may be reproduced, distributed, or transmitted, unless for course participants. All rights reserved.

- Between lectures during the course, the instructor(s) will be available via email for technical questions and comments.

AIAA Training Links

-

For information, group discounts,

and private course pricing, contact:

Lisa Le, Education Specialist ([email protected])